Mechanical clocks, with their intricate gears and springs, are marvels of precision engineering. However, even the best timepieces can experience timekeeping issues. Understanding how to troubleshoot these problems can help you keep your clock running accurately. Here’s a guide to identifying and fixing common timekeeping issues in mechanical clocks.

1. Check the Power Source

Start by ensuring your clock has a reliable power source. Mechanical clocks are typically powered by a mainspring. If your clock is running slow or stopping, the mainspring might be unwound or broken.

- Wind the Clock: If the clock has stopped, try winding it fully. Mechanical clocks need regular winding to operate correctly.

- Inspect the Mainspring: If winding doesn’t solve the issue, the mainspring might be damaged or broken.

Transition to examining the clock’s movement if the power source seems fine but the timekeeping is still off.

2. Examine the Movement

The movement is the heart of a mechanical clock. If it’s dirty or misaligned, it can affect timekeeping.

- Clean the Movement: Dust and grime can cause friction, leading to inaccurate timekeeping. Use a soft brush to remove dust and a clock-specific cleaner for thorough cleaning.

- Check for Obstructions: Ensure no debris or foreign objects are obstructing the gears.

Transition to inspecting the clock’s escapement if the movement seems clean and clear but issues persist.

3. Inspect the Escapement

The escapement controls the release of energy from the mainspring to the gears. Issues with the escapement can lead to irregular timekeeping.

- Check the Pallets: Make sure the pallets, which interact with the escape wheel, are clean and not worn out.

- Adjust the Beat Rate: The beat rate is how often the escapement ticks. If it’s uneven, adjust the beat rate using the regulating screw or lever.

Transition to examining the pendulum or balance wheel for additional timekeeping problems.

4. Examine the Pendulum or Balance Wheel

The pendulum or balance wheel regulates the timekeeping in most mechanical clocks. Problems here can directly affect accuracy.

- Pendulum Adjustment: If your clock has a pendulum, check its length and ensure it’s hanging properly. Adjust the pendulum’s rating nut to fine-tune the timekeeping.

- Balance Wheel Inspection: For clocks with balance wheels, ensure the wheel oscillates smoothly and that the hairspring is not tangled.

Transition to evaluating the clock’s hands and dial if the pendulum or balance wheel appears in good condition.

5. Check the Hands and Dial

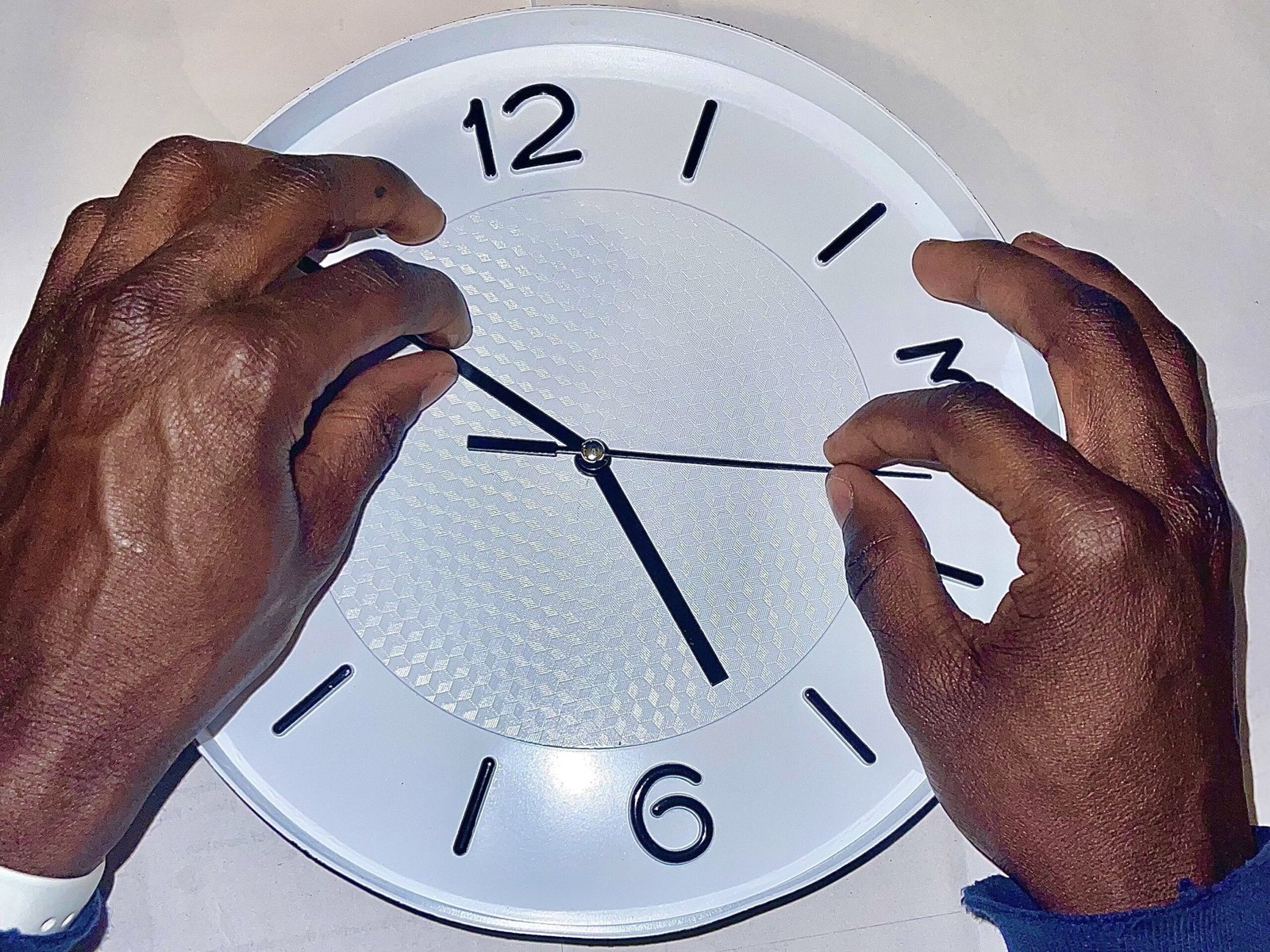

Misalignment or interference with the clock’s hands can cause inaccurate timekeeping.

- Ensure Proper Alignment: Check if the hands are properly aligned and not touching each other or the dial.

- Inspect for Obstructions: Ensure no debris or damage is preventing the hands from moving freely.

Transition to calibrating the clock if all components appear to be functioning correctly.

6. Calibrate the Clock

Calibration involves fine-tuning the clock to ensure it keeps accurate time.

- Use a Timekeeping Device: Compare your clock to a reliable timekeeping source. Adjust the clock’s time as needed using the regulating screw or lever.

- Monitor Performance: After adjustment, monitor the clock for a day or two to ensure it maintains accurate time.

7. Seek Professional Help

If troubleshooting doesn’t resolve the issue, consider consulting a professional. Complex problems may require expert attention.

- Find a Specialist: Look for a reputable clock repair specialist who can diagnose and fix intricate issues.

- Regular Maintenance: Schedule regular maintenance with a professional to keep your clock in top condition.

Conclusion

Troubleshooting timekeeping issues in mechanical clocks involves checking the power source, movement, escapement, pendulum or balance wheel, and hands. By systematically examining each component, you can often identify and resolve common problems. Regular maintenance and proper calibration are key to keeping your mechanical clock running accurately. If issues persist, don’t hesitate to seek professional help to ensure your timepiece continues to function perfectly.